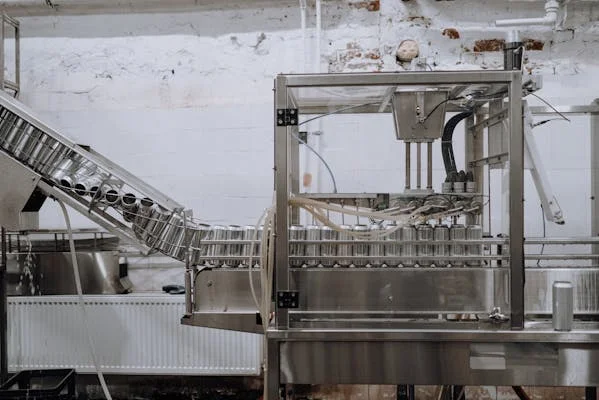

In today’s fast-paced global market, ensuring food safety is paramount. sterilization technology involved in food line in food lines is the process of eliminating or reducing harmful microorganisms, such as bacteria, viruses, and spores, from food products. This technology not only prevents foodborne illnesses but also plays a significant role in maintaining product quality, extending shelf life, and complying with global food safety regulations. Modern food processing facilities integrate advanced sterilization technologies to meet consumer demand for safe, nutritious, and ready-to-eat products. As we explore this topic, you’ll gain insight into various sterilization methods, the science behind them, and the technological innovations that are shaping the future of food processing.

The Importance of Sterilization in the Food Industry

Sterilization technology is crucial for several reasons. Its application in the food industry has far-reaching impacts on public health, consumer confidence, and economic growth.

Enhancing Food Safety and Extending Shelf Life

- Eliminating Pathogens: Effective sterilization processes reduce or eliminate harmful microorganisms that can cause foodborne diseases.

- Shelf Life Extension: By controlling microbial growth, sterilization technology helps prolong the shelf life of perishable food items, reducing food waste and boosting economic efficiency.

- Quality Maintenance: Sterilization ensures that food retains its intended texture, flavor, and nutritional profile while minimizing spoilage.

Building Consumer Trust and Meeting Regulatory Standards

- Regulatory Compliance: Stringent global food safety standards demand robust sterilization processes. Compliance ensures that food products are safe for consumption and meet legal requirements.

- Consumer Confidence: Transparent sterilization practices and certifications build trust among consumers, who are increasingly concerned about the safety of the food they consume.

- Brand Reputation: Consistent quality and safety bolster brand reputation, encouraging repeat purchases and customer loyalty.

Types of Sterilization Technologies in Food Lines

The food industry employs a range of sterilization techniques, each with its unique advantages. Understanding these methods helps in selecting the appropriate technology for specific food products.

Thermal Sterilization (Heat Processing)

Thermal sterilization is one of the oldest and most widely used methods in the food industry.

- Retorting: Involves placing food in sealed containers and subjecting it to high-pressure steam or water at elevated temperatures. This method is particularly effective for canned foods.

- Pasteurization: A milder form of heat treatment that targets pathogens without significantly altering the food’s flavor or nutritional content. Commonly used for dairy products, juices, and liquid eggs.

- Ultra-High Temperature (UHT) Processing: Involves heating food products to extremely high temperatures for a short duration, effectively sterilizing the product while preserving taste and nutritional quality.

Non-Thermal Sterilization Technologies

Non-thermal methods offer alternatives to heat-based sterilization, often preserving the sensory and nutritional attributes of food better.

- High Pressure Processing (HPP): Uses extremely high pressure to inactivate microorganisms. This method is effective for preserving fresh, minimally processed foods.

- Ultraviolet (UV) Radiation: UV light disrupts the DNA of microorganisms, rendering them inactive. UV sterilization is commonly used for surface treatments and liquid food products.

- Pulsed Electric Field (PEF) Technology: Applies short bursts of high voltage to food products, leading to cell membrane disruption in microorganisms without significant heating.

- Chemical Sterilization: Involves using chemical agents (e.g., ozone or hydrogen peroxide) to eliminate pathogens. This method is used in conjunction with other techniques to ensure thorough sterilization.

Emerging Technologies in Food Sterilization

Innovation in sterilization technology continues to evolve, offering new solutions to meet modern challenges.

- Cold Plasma Technology: Uses ionized gas to generate reactive species that effectively inactivate microbes without affecting the food’s quality.

- Microwave Sterilization: Leverages microwave energy to heat food products rapidly and uniformly, ensuring effective microbial control while reducing processing times.

- Advanced Filtration Systems: Incorporate nanotechnology and membrane filtration to remove pathogens at a microscopic level, offering an extra layer of safety in food production.

The Sterilization Process in Food Lines

A robust sterilization process is essential for ensuring that food products remain safe and high-quality throughout the production cycle. This process typically involves several critical stages.

Pre-Treatment and Food Preparation

- Raw Material Inspection: Before sterilization, raw materials are thoroughly inspected to ensure they meet quality standards. This includes testing for contaminants and microbial load.

- Pre-Cleaning: Food items are washed and sanitized to remove surface impurities, reducing the microbial load before the sterilization process begins.

- Pre-Treatment Processes: Some food products may undergo pre-treatment steps such as blanching or chemical washes to enhance the effectiveness of subsequent sterilization.

Implementing the Sterilization Process

- Selection of Appropriate Technology: Depending on the product type and desired shelf life, manufacturers choose between thermal, non-thermal, or emerging sterilization methods.

- Process Optimization: Parameters such as temperature, pressure, exposure time, and chemical concentrations are optimized to maximize microbial inactivation while preserving food quality.

- Automation and Monitoring: Modern sterilization units are integrated with advanced sensors and control systems, ensuring precise and consistent application of sterilization treatments.

Post-Sterilization Packaging and Storage

- Aseptic Packaging: After sterilization, food products are packaged in sterile environments to prevent recontamination. Technologies such as aseptic filling ensure that products remain free from pathogens.

- Storage Conditions: Controlled storage conditions, including temperature and humidity regulation, further help maintain product safety and quality.

- Quality Assurance: Routine testing and monitoring during storage verify that the sterilization process has been effective and that no microbial contamination has occurred.

Key Factors for Effective Sterilization Technology

Implementing a successful sterilization process in food lines requires a holistic approach that considers various technical and environmental factors.

Equipment and Machinery Considerations

- High-Quality Machinery: Investing in reliable, state-of-the-art sterilization equipment is crucial. Quality machinery not only improves efficiency but also ensures consistent treatment across batches.

- Maintenance and Calibration: Regular maintenance and calibration of equipment are vital to maintaining the efficacy of sterilization processes. This ensures that operational parameters remain within optimal ranges.

- Scalability and Flexibility: Modern sterilization systems should be scalable to accommodate different production volumes and adaptable to various food products.

Process Validation and Quality Control

- Continuous Monitoring: Real-time monitoring systems help ensure that sterilization parameters are maintained throughout the process. Automated systems can detect deviations and trigger corrective actions immediately.

- Regular Testing: Microbiological testing before and after sterilization validates the effectiveness of the process. Documentation of these tests is critical for regulatory compliance.

- Standard Operating Procedures (SOPs): Implementing and adhering to detailed SOPs ensures that every step of the sterilization process is performed consistently and correctly.

Environmental Impact and Sustainability

- Energy Efficiency: As the food industry moves toward sustainable practices, energy-efficient sterilization technologies are gaining prominence. Reducing energy consumption not only lowers operational costs but also minimizes environmental impact.

- Waste Management: Proper disposal of sterilization by-products and chemical residues is essential to prevent environmental contamination.

- Eco-Friendly Technologies: The adoption of eco-friendly sterilization methods, such as cold plasma and UV radiation, is a growing trend, aligning with global sustainability goals.

Challenges in Implementing Sterilization Technology in Food Lines

Despite its many benefits, the implementation of sterilization technology in food lines comes with several challenges that manufacturers must navigate.

Cost Implications and Investment

- High Initial Investment: Advanced sterilization equipment and technology require significant upfront capital, which can be a barrier for smaller manufacturers.

- Operational Costs: Energy consumption, maintenance, and regular calibration contribute to ongoing operational expenses.

- Return on Investment (ROI): Balancing the initial costs with long-term benefits is essential. Manufacturers must evaluate the ROI in terms of improved shelf life, reduced spoilage, and enhanced consumer trust.

Maintaining Nutritional Quality and Sensory Attributes

- Overprocessing Risks: Excessive heat or chemical treatments can degrade essential nutrients and alter the sensory attributes of food, such as taste, texture, and color.

- Process Optimization: Finding the optimal balance between effective sterilization and preservation of food quality remains a continuous challenge. Manufacturers must continually refine processes to avoid compromising the product.

Regulatory and Compliance Challenges

- Varying Global Standards: Different countries have different regulatory requirements for food sterilization. Manufacturers must navigate these complexities to ensure global market access.

- Documentation and Traceability: Maintaining comprehensive records of sterilization processes is essential for compliance and quality assurance. This requires robust data management systems and regular audits.

- Innovation vs. Regulation: While emerging sterilization technologies offer promising advantages, regulatory bodies must evaluate and approve these methods, which can slow down their adoption.

Future Trends and Innovations in Food Sterilization Technology

The field of food sterilization is rapidly evolving, driven by technological innovations and changing consumer expectations.

Integration of IoT and AI in Process Monitoring

- Smart Sensors: The integration of IoT devices in sterilization equipment enables real-time monitoring of temperature, pressure, and microbial counts, ensuring precise control over the process.

- Data Analytics: AI-powered analytics can predict process deviations and optimize parameters, leading to more efficient and consistent sterilization outcomes.

- Predictive Maintenance: Advanced systems can forecast equipment maintenance needs, reducing downtime and ensuring continuous operation.

Sustainable and Energy-Efficient Solutions

- Green Technologies: Innovations such as cold plasma, UV, and microwave sterilization offer environmentally friendly alternatives to traditional thermal methods.

- Renewable Energy Integration: The use of renewable energy sources to power sterilization processes is gaining traction, reducing the carbon footprint of food processing facilities.

- Waste Reduction: Technologies that minimize waste and chemical residues contribute to a more sustainable food production cycle.

Personalized and On-Demand Sterilization Processes

- Modular Systems: Future sterilization systems may offer modular designs that can be easily scaled and customized based on production needs.

- Flexible Production Lines: As consumer demand shifts toward personalized nutrition and smaller batch production, sterilization technology involved in food line will need to adapt to more flexible production models.

- Real-Time Adjustments: The ability to adjust sterilization parameters on the fly, using real-time data, will be crucial for meeting the dynamic demands of modern food production.

Case Studies: Success Stories in Food Sterilization

Examining real-world examples of sterilization technology involved in food line in action can provide valuable insights into best practices and potential pitfalls.

Dairy and Beverage Industry

- Extended Shelf Life: Many dairy companies have successfully implemented UHT processing to extend the shelf life of milk and other beverages without compromising taste.

- Consumer Safety: Robust sterilization processes have significantly reduced the incidence of foodborne illnesses in dairy products, thereby enhancing consumer trust.

- Innovation Adoption: The integration of automated monitoring systems in dairy plants has ensured consistent process control and high-quality output.

Ready-to-Eat Meals and Processed Foods

- Quality Assurance: Ready-to-eat meal producers have adopted High Pressure Processing (HPP) to ensure that fresh ingredients are safely processed while retaining nutritional value.

- Regulatory Compliance: Companies that have embraced advanced sterilization methods are better positioned to meet strict global regulatory standards, facilitating international market expansion.

- Reduced Waste: Improved shelf life through effective sterilization minimizes food waste, contributing to more sustainable production practices.

Best Practices for Implementing Sterilization Technology in Food Lines

To maximize the benefits of sterilization technology involved in food line while mitigating challenges, manufacturers should adopt a set of best practices.

Regular Maintenance and Calibration of Equipment

- Scheduled Inspections: Establish regular maintenance schedules to ensure that all sterilization equipment operates within specified parameters.

- Calibration Protocols: Implement strict calibration procedures to maintain accuracy and efficiency in the sterilization process.

- Equipment Upgrades: Stay informed about the latest technological advancements and consider upgrading machinery to improve performance and safety.

Continuous Staff Training and Process Improvement

- Employee Training Programs: Regularly train staff on the latest sterilization techniques, safety protocols, and equipment handling to ensure a high standard of operation.

- Process Audits: Conduct routine audits of sterilization processes to identify areas for improvement and implement corrective measures promptly.

- Feedback Mechanisms: Encourage feedback from employees and quality control teams to refine and enhance sterilization protocols continuously.

Monitoring and Documentation of Sterilization Processes

- Comprehensive Record-Keeping: Maintain detailed records of all sterilization processes, including temperature, time, pressure, and microbial test results, to ensure traceability and regulatory compliance.

- Real-Time Data Logging: Utilize digital systems for real-time monitoring and data logging to quickly identify and rectify any deviations from standard operating procedures.

- Quality Assurance Programs: Implement robust quality assurance programs that include regular microbial testing and process validation to ensure the highest level of food safety.

Conclusion

sterilization technology involved in food line is at the forefront of ensuring food safety, quality, and sustainability in the modern food industry. By adopting a combination of traditional thermal methods and innovative non-thermal approaches, food manufacturers can effectively eliminate pathogens, extend shelf life, and maintain the nutritional integrity of their products. The integration of advanced technologies such as IoT, AI, and sustainable energy solutions is setting the stage for a new era in food processing—one where efficiency, precision, and environmental responsibility go hand in hand